Heat Treatment Oven Build Process

Page 25 of 35

Posted 2nd February 2025

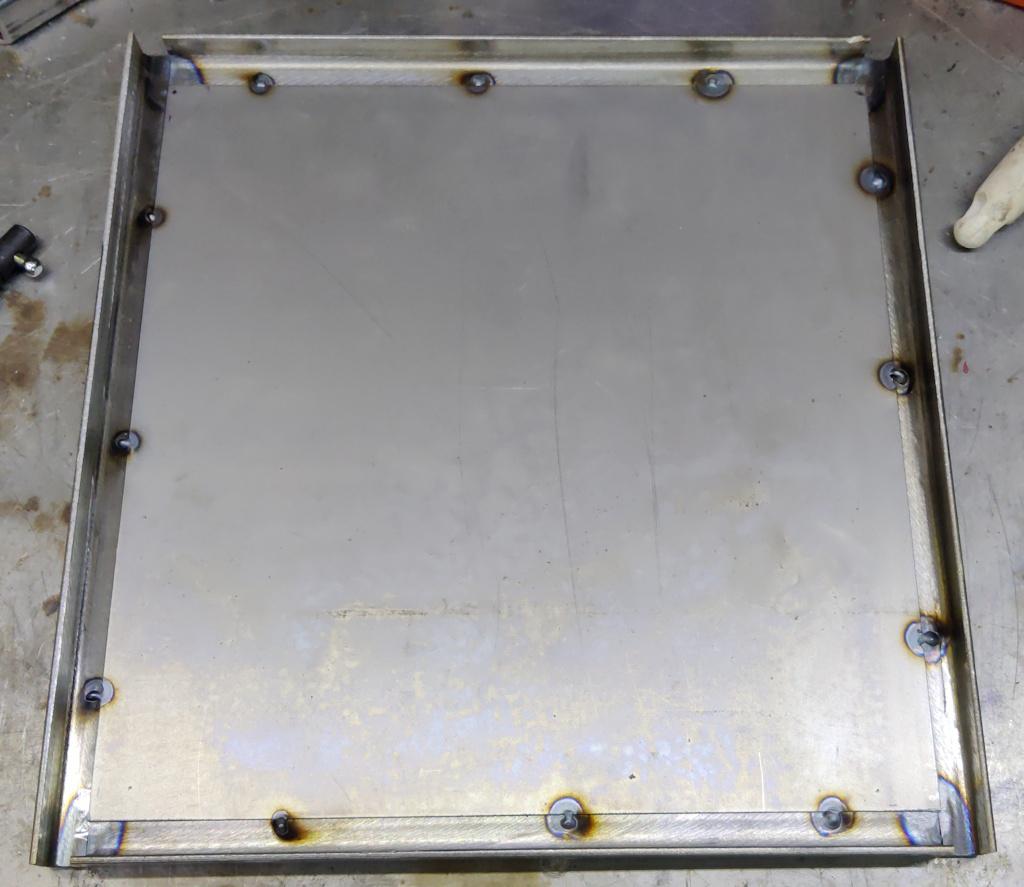

To make the door, I started by making a similar frame to the ones I made for the body:

You may notice that there are some gaps at the ends: that's a result of not having any bits of 20 mm angle iron that were quite long enough. They were long enough to be able to join them, so I figured I'd sort out the gaps later.

The control cabinet has three thermocouple inputs on the side. The idea of that is that one thermocouple is used for temperature control, one is used for the over temperature safety trip and one is just for monitoring and seeing how the temperature varies across the oven. With two thermocouples coming through holes at the back, it made sense to me that the third one would come through a hole in the door. To that end, I made another 50 mm wide cross bar to go across the front. This time I decided to drill the holes in the sheet before fitting the cross-bar:

Those holes meant I could tack the sheet to the cross-bar in the middle, which was probably unnecessary, but won't hurt:

By this point I was almost out of 20 mm angle iron, but I'd also thought that I wanted to support the door bricks a bit better (with more overlap), so I cleaned up (with a flap disc in the angry grinder) some 30 mm angle iron and made a frame out of that:

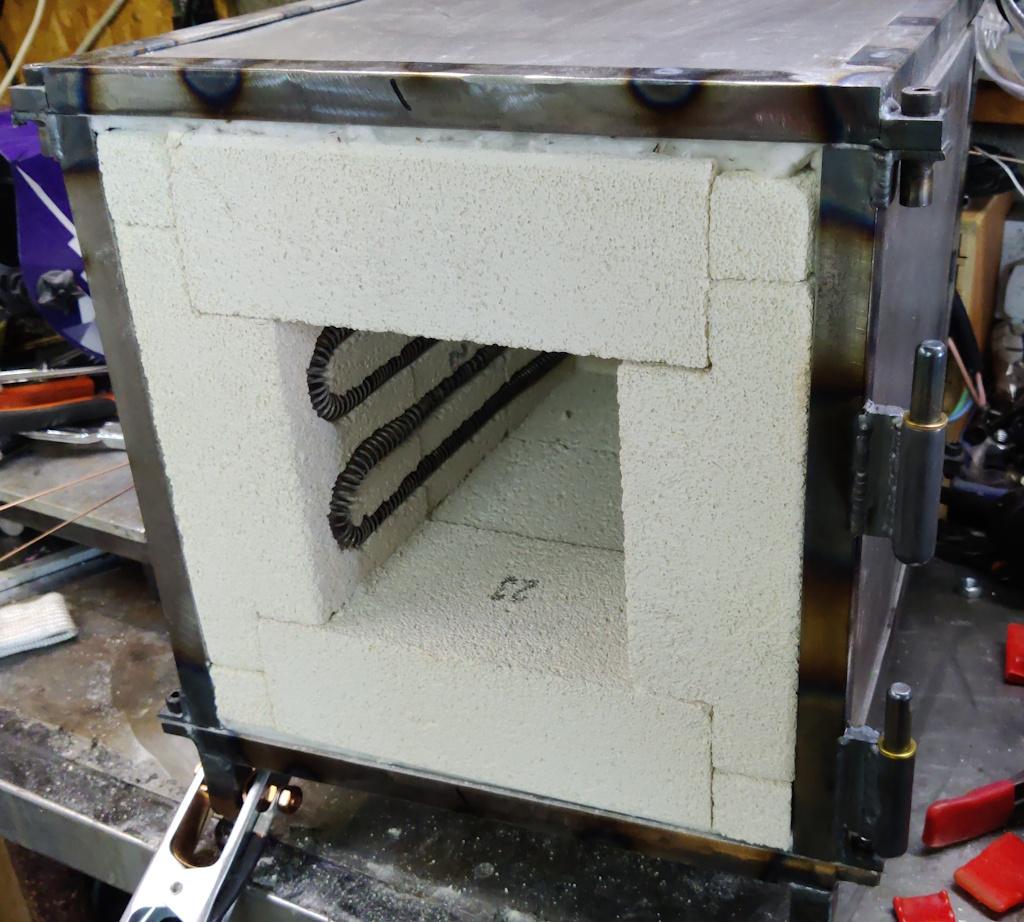

I could then cut some bricks to size and fit them in the first frame (this time not leaving any space around the edges for ceramic fibre blanket as I want the second frame to hold the bricks as firmly as possible):

After marking where the second frame would sit, I used a saw to cut a shallow rebate around all the bricks:

I'd be intending to that with one of these Stanley Surform things (which I inherited but have never used), but I couldn't figure out where I'd stored it, so I just did it carefully with the saw and it seemed to go okay. All the bricks rebated:

I could then use my small remaining collection of 20 mm angle iron to make the joining pieces. I cut them with a little tongue on the end so that they could fill in that unsightly gap at the same time as forming the remaining sides of the frame:

They then got tacked in place to the first frame only:

After finishing the welding to the first frame, I dismantled it all, cut some bits of sheet steel to size and tacked them in place:

They won't get welded to the other frame (as it'll be impossible to do so. The door then got welded together with bricks in place:

Unlike the main body of the chamber (which I can dismantle with screws), I decided to just weld the door together. Hopefully it'll be robust and will never need to come apart (the bricks don't have slots cut in them so should be less fragile). If it ever does need to come apart it'll have to be done with a slitting disc in an angle grinder.

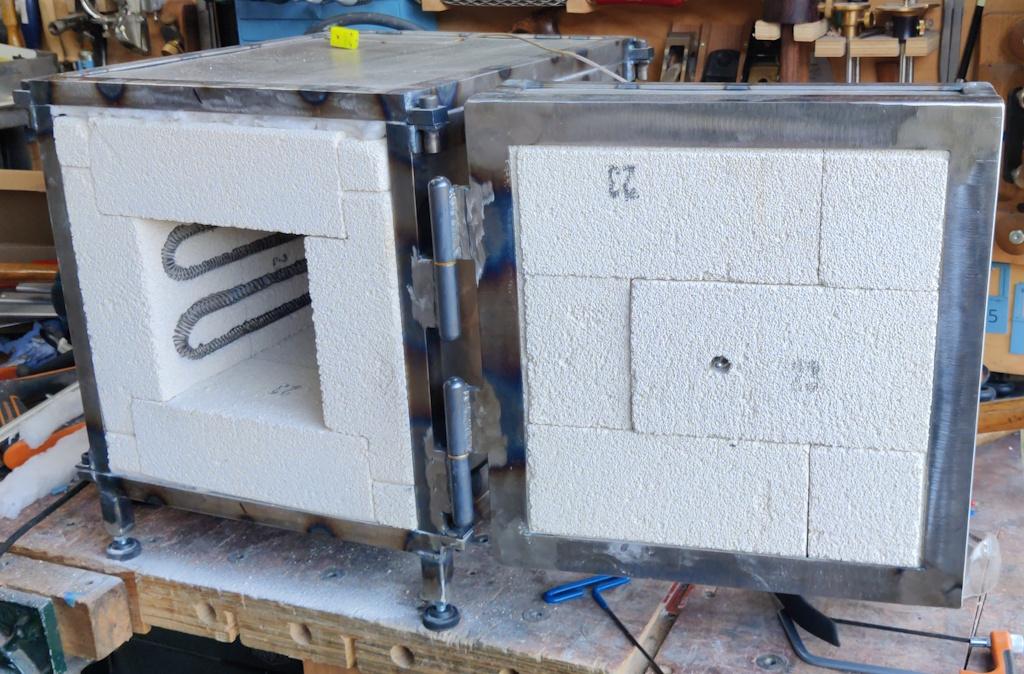

With all the joints welded, the door was complete and ready for mounting:

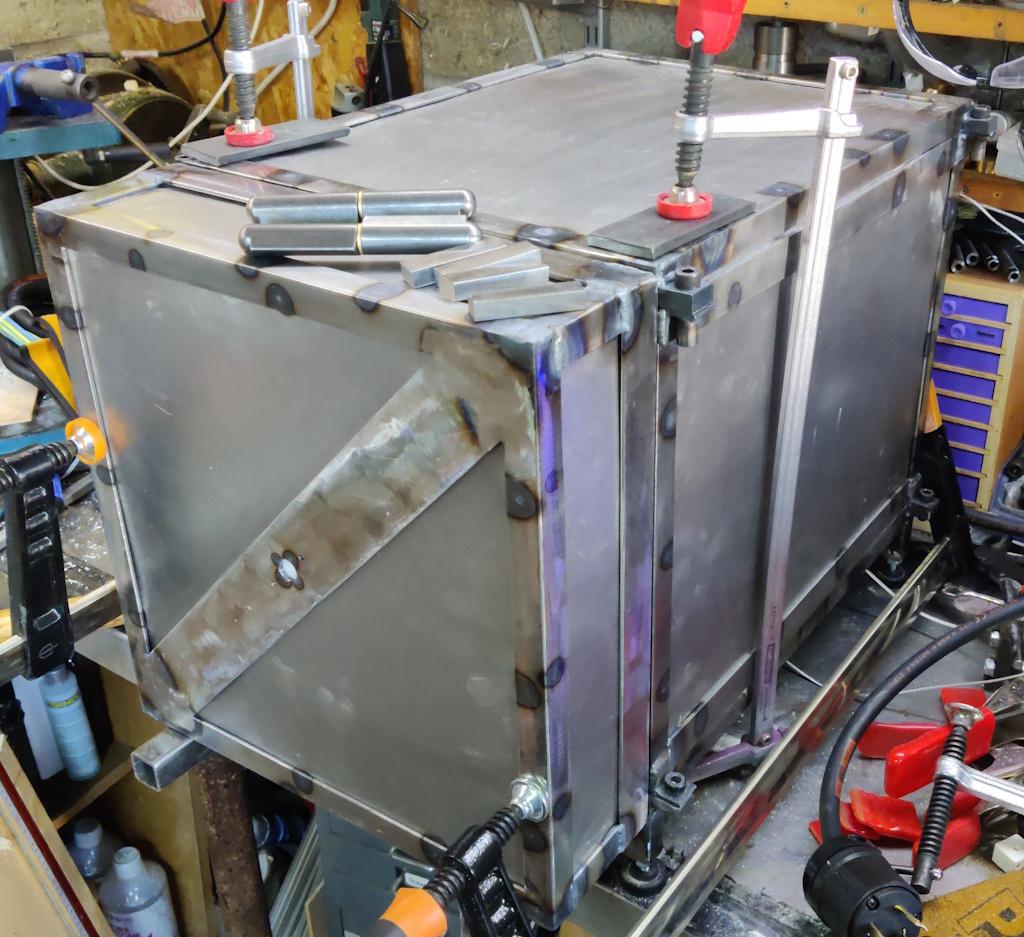

To mount the door, I brought the chamber body down to the metalwork end of the garage and clamped the door in place:

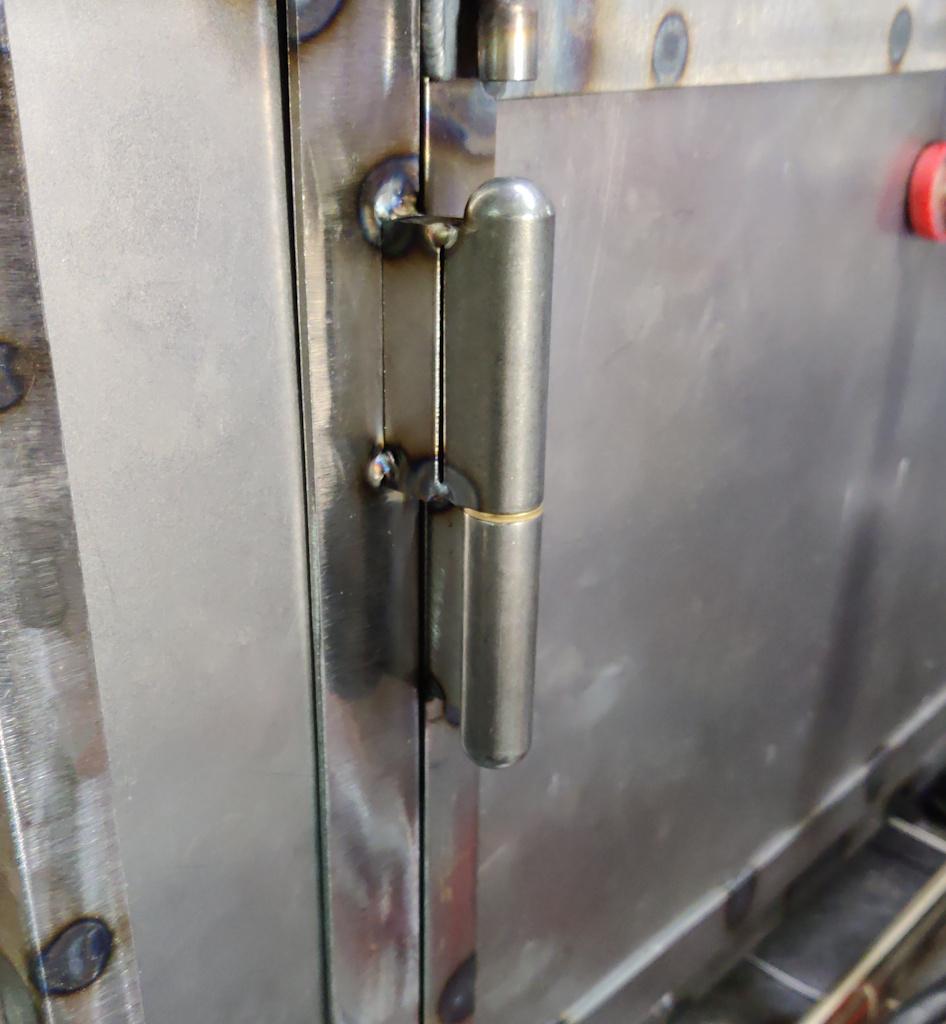

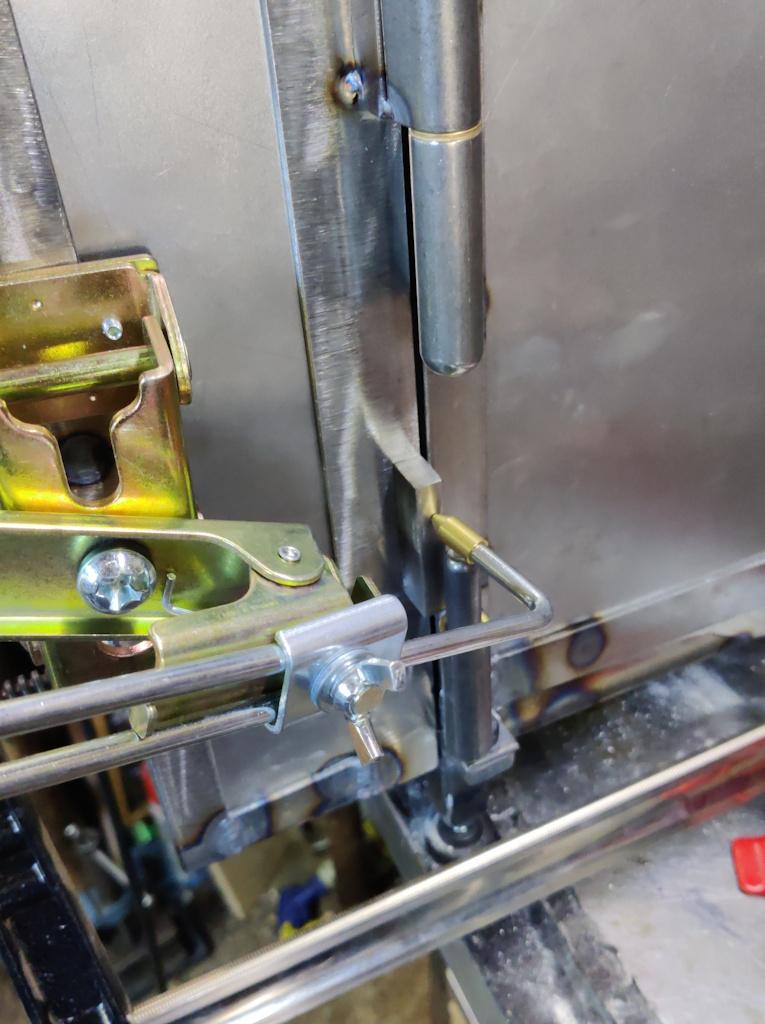

I cut a few 50 mm long bits of steel bar so that I could offset the hinges and avoid any of the rubbing problems I had on the control cabinet:

This is where the magnetic hold down clamp I've got really comes into its own as it can hold the block in place while I tack it, despite the fact that it's on the side of the chamber:

After tacking the first block, I tacked the first half of the bullet hinge in place, then positioned the second block, tacked that and finally tacked the other half of the bullet hinge:

The magnetic hold-down was also useful for the second block in each pair:

At that point, the door could be unclamped and it opened and closed very easily. I took the door off the chamber and welded the hinge pieces properly to the body (which was a bit awkward given the angles)...

... and then did the same with the door (which was a lot easier):

I then tried to fit the door and found that the hinges wouldn't go back together. I've never mastered welding stuff without movement and I think this is what happened: the hinges must have moved a bit when I did the final welding. To sort it out, I drilled the bottom door hinge out slightly larger (to give a bit more lateral tolerance) and with that done it went together fairly easily and moves freely:

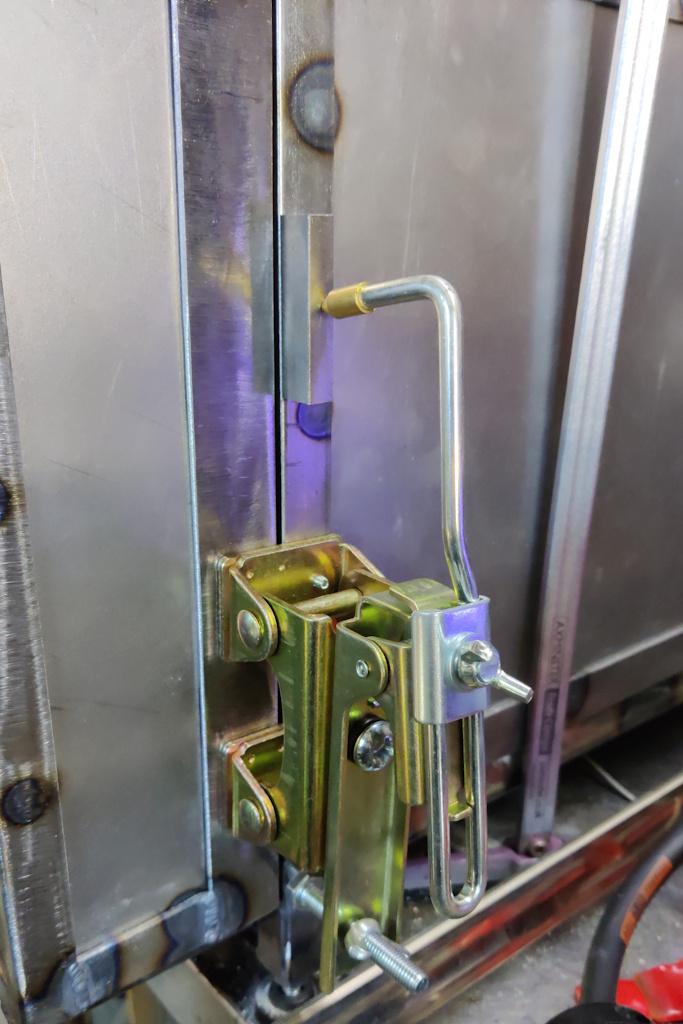

The last big job on the chamber (ignoring painting) is to figure out some sort of latch mechanism to hold the door shut. I haven't really had any thoughts about that yet, so I guess I'll do some web searching during the week.

Another consideration is whether to cut a channel in the door bricks for a fire rope to help seal it, but it feels to me at the moment that the brick-on-brick seal of the door to the chamber will be as good as the brick-on-brick seal elsewhere in the chamber, so I'm currently thinking that I won't bother with the fire rope. Comments / suggestions are welcome as usual.

Page 25 of 35

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page