Heat Treatment Oven Build Process

Page 27 of 35

Posted 8th February 2025

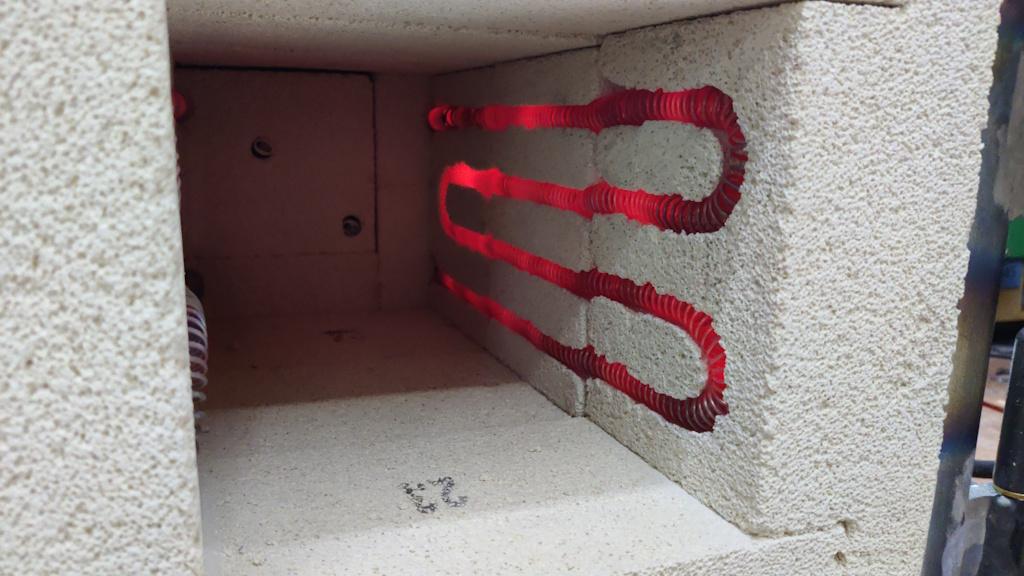

It's alive, alive!

That photo was taken with the chamber at about 100°C and with the EPack configured for 2000 W. So far I've taken it up to a little over 320°C. I set it for 324°C (the potentiometer is a bit sensitive for picking a round number: I perhaps should have gone with a multi-turn one!). There was about 12°C of overshoot (peaking at a reported 336.2°C) and then it looked like it was going to undershoot as well once the temperature started to drop. That's not especially surprising: I doubt the integral bit of the PI controller is well tuned to the chamber. I'll do some digging and see if there are any auto-tune methods (I'd be surprised if there aren't on a controller this fancy).

One of the thermocouples on the back of the chamber was giving an invalid reading. I'm not sure why (it might be as simple as my having wired the connections the wrong way round), but I'll wait until everything's cooled down before investigating. Worst case it'll be easy to replace. For the test I just used a low-temperature thermocouple to feed the over-temperature trip (which is okay while I'm standing there watching it like a hawk!).

There seems to be a pretty consistent 25°C-ish difference between the temperature at the back of the chamber (used for control, shown as Channel 2 in the photo above) and that recorded by the door thermocouple (shown as Channel 3 in the photo above). I'd expect some difference (they're measuring the temperature in different places), but I was surprised by the size of the difference, especially since they both started dropping at the same time (vs the door thermocouple just lagging behind the measurement at the back). I suspect there's a calibration issue there somewhere, but I'm not really sure how to calibrate them. I can envisage taking more controlled measurements at relatively low temperatures (less than about 200°C) to check the measurements, but up at the higher levels it could be a lot more difficult.

Anyway, it seems to be fundamentally working, which is great! Nothing "exciting" happened as it heated up to 330°C and the the steel-work all felt cold to the touch. I've turned the heater switch off for now (but left the control power on so the temperature is still monitored) and will let it cool completely. Then I'll have a bit of a rummage inside to see whether anything moved around (e.g. to see if bits fell off the bricks) before heating it up a bit more. I might also increase the set-point to 3 kW, which is about the maximum it'll produce.

Page 27 of 35

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page