Heat Treatment Oven Build Process

Page 28 of 35

Posted 8th February 2025

After getting back from a long lunch with some friends, I went to check on the chamber. It had been at 210°C when I turned it off and, 2½ hours later, it had dropped to 100°C, which seemed pretty good to me (i.e. the insulation can't be too bad if it holds that much heat for that long).

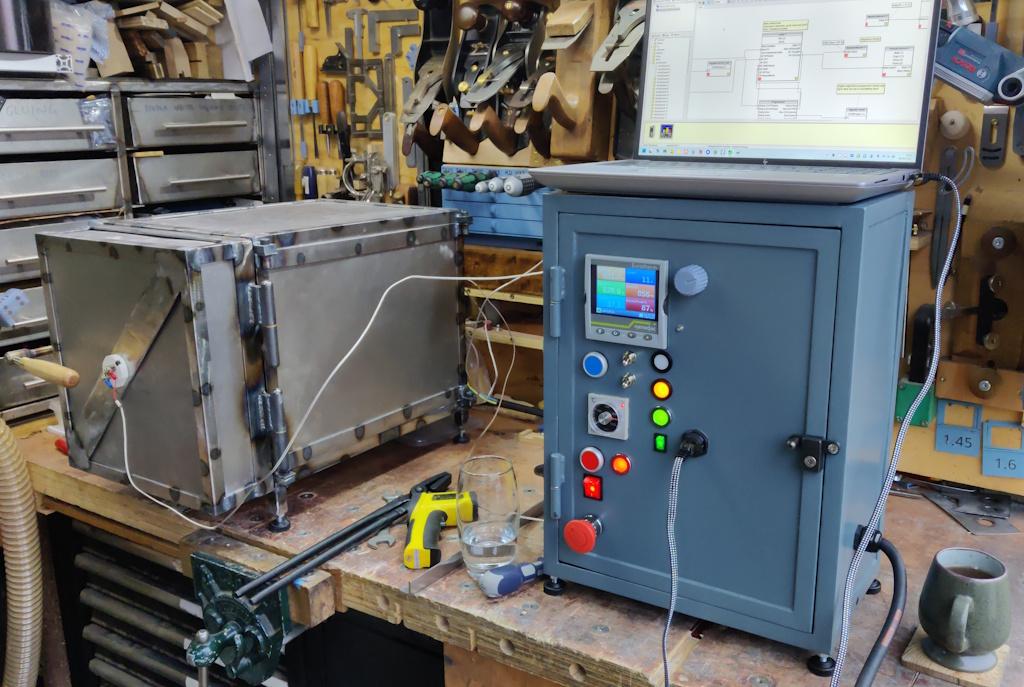

Rather than carting the control cabinet up and down the garden path, I decided to take the laptop out to the garage to do some experimenting with settings:

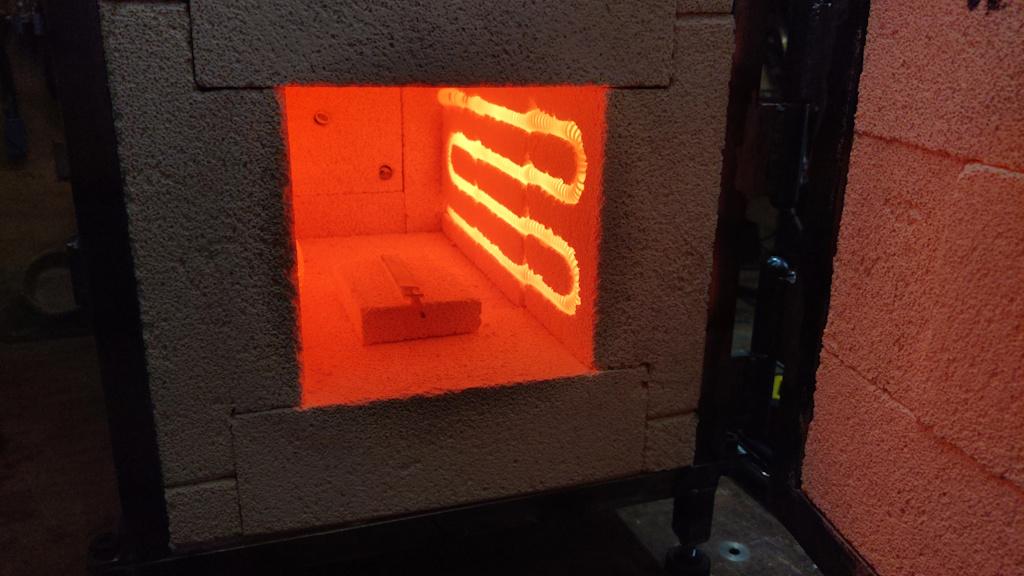

I changed the EPack power up to 3 kW, tweaked the display settings of the Nanodac so it showed the demand to the EPack (because I was interested) and also ran the auto-tune algorithm with the set-point configured at 570°C. After that, I thought I'd wind it up a bit hotter and see how it went. The auto-tune obviously worked as there was very little overshoot on its way up to the (rather random) target of 856°C:

I was standing there expecting to here lots of little noises (creaks etc) as things moved in the chamber, but it was surprisingly uneventful really. Nothing happened apart from it getting very hot! I opened the door and chucked an old file in:

While the door was open, I also pointed a cheap infrared temperature sensor at the bricks and it reported something in the region of 860°C, so at least that tells me the thermocouples can't be that far off!

Over the next hour or two, I gradually reduced the temperature down to about 450°C and then turned the chamber off. I doubt that'll be a slow enough rate of cooling to anneal the file I put in there, but I didn't have the patience to turn the dial down any slower. In due course I'll set up a program (controlled by one of the switches) to do a really slow rate of change of temperature automatically. That will be useful when I want to anneal something.

For now, I'll leave the chamber to fully cool down overnight. It'll be interesting to see how hard the file is in the morning, but I won't be disappointed if it's still a bit hard. Tomorrow I'm going to fit the door interlock as the first job and then do some investigation into what's going on with the errant temperature sensor.

For today though, I'm really happy with how it all went. There's still lots to do, including taking an angle grinder to the remaining sharp corners, painting it and putting a bit more effort into the Nanodac programming, but it feels like today was a major milestone.

Page 28 of 35

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page