Woodturning Lathe Build Process

Page 35 of 57

Posted 31st March 2024

I had another go at a bowl yesterday and it went a bit better this time, although I wouldn't go so far as to say I enjoyed the process. I started with the other half of the bit of sycamore that I turned the last bowl out of. I mounted it using a screw chuck and turned the outside with the bowl gouge. That went fairly smoothly (and the 3d-printed speed sizer thing worked well again):

It then got reversed and held on the dovetailed base and the inside was turned. This went a lot better than last time - I don't think I'd realised that I needed to have the handle end of the bowl gouge right over the far side of the lathe. A shorter handle would probably have helped: the bench top kept getting in the way!

Anyway, it went okay-ish (there was still a fairly amount of scraping to tidy things up, followed by lots of sanding, but no actual catches). Overall though, I didn't really enjoy making it and I can't see me making many more bowls, so I guess I don't have to lose too much sleep over whether my technique is quite right or not.

I also finished off the shaping of the rest of the handles yesterday:

They had their first coat of Mike's Magic Mix yesterday and the second one today (I'll probably leave it at two coats):

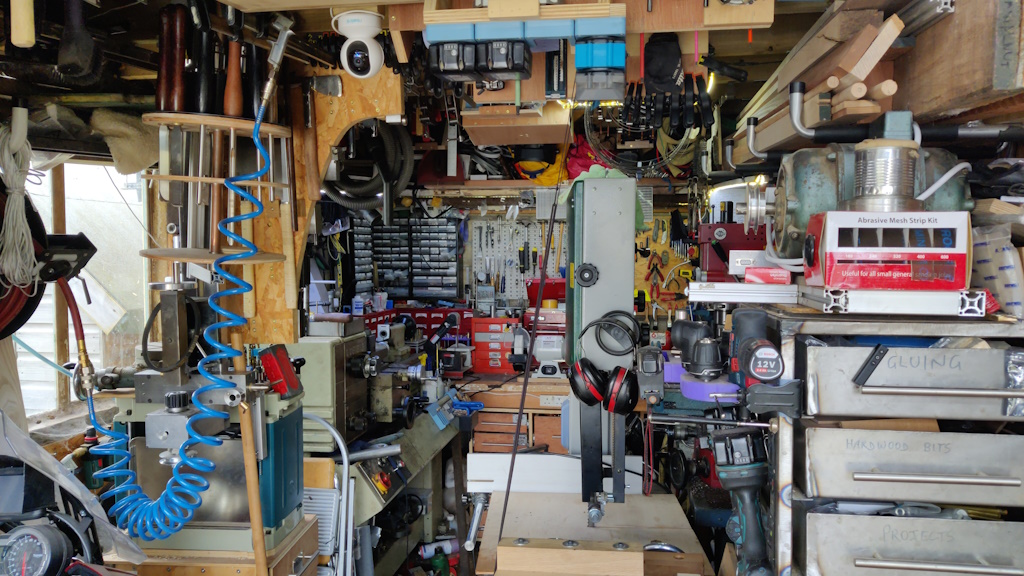

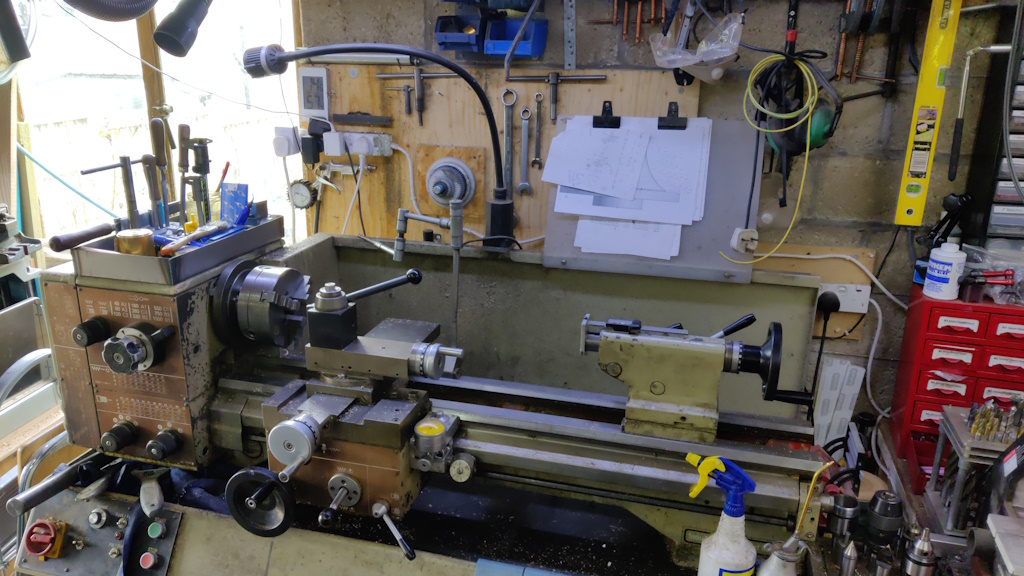

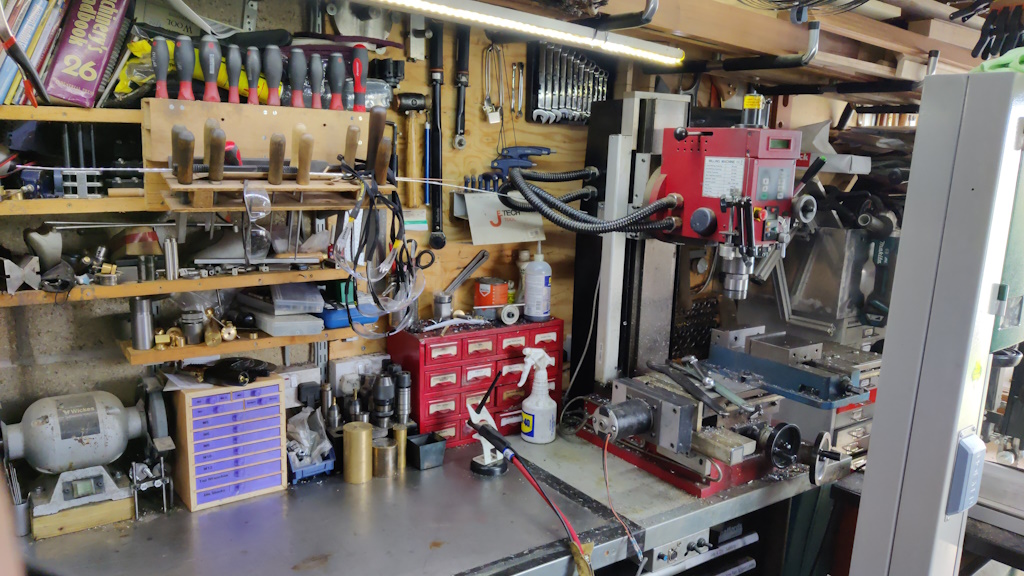

I've spent almost the entirety of today tidying the workshop. It was in an awful state and it had been a long time since I last had two clear benches. It was a real struggle at times to figure out what to do with some of the stuff, but in the end it came out looking good, so I took some photos (something I try to do on the rare occasions that the workshop is tidy!)

Page 35 of 57

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page