Woodturning Lathe Build Process

Page 44 of 65

Posted 21st December 2025

I've decided to give the lathe a bit of a service and some minor updates. Having used it quite a lot earlier in the year making lots and lots of bowls, I've convinced myself that the lathe works perfectly well, but there are a few minor niggles that I'd like to address.

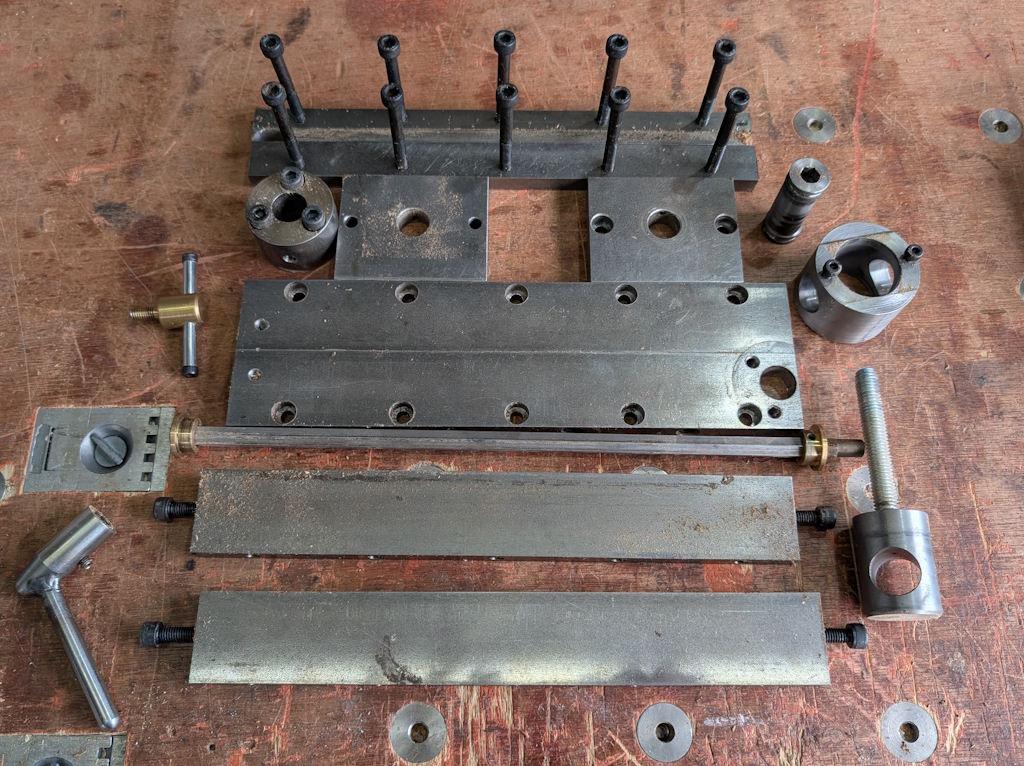

The first thing I did was dismantle the lathe:

The four plastic cylinders you can see behind all the lathe bits are some custom made bearing fitting/removing tools, three of which were 3D-printed and the fourth (which is just a cylinder with a hole in it) turned on the lathe out of some unknown plastic.

After taking that photo, I also decided to disassemble the banjo:

The main focus for the work will be these three parts:

The tailstock is going to gain a cam-lock, which should improve the ergonomics a little. I'm going to make a completely new spindle (again!) and the headstock will get quite a few minor modifications, mostly involving drilling / tapping extra holes in it.

There are a few other modifications that will happen as well, mostly involving this little pile of material that (with the exception of the 50 mm EN1A bar at the front) came out of a skip:

The 50 mm EN1A bar will become the new spindle (turned from solid this time rather than made in two parts with an interference fit). The lump of aluminium at the back will be cut in half and made into a new lid for the headstock. Only one of the discs will be used (but I haven't decided which yet).

More to follow; watch this space!

Page 44 of 65

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page