Woodturning Lathe Build Process

Page 45 of 65

Posted 21st December 2025

I decided to start with the new spindle. There are two reasons I want to do this, neither of which are really essential (and if I wasn't making other modifications to the lathe at the same time I doubt I would have bothered).

The first and arguably more important change is that I'm going to extend the rear of the spindle a bit (so it sticks further out from the back of the headstock). The reasons for that will become clear later.

The other change is that I'm going to tweak the shape of the spindle nose to match the ASR standard (a drawing of which I've managed to find on the web). The ASR standard includes an angled face on the rear of the register upon which the chuck bears. That angled face can be used with a clamp to hold the chuck on the spindle and stop it unscrewing (if the lathe is run backwards or when stopping if the chuck has significantly more momentum than the spindle).

Whether I'll ever use said clamp remains to be seen!

This ASR clamp is the reason I decided to make the spindle out of solid bar rather than doing an interference fit as before. If I just added the angled face onto the existing spindle, the clamp would bear on the 50 mm piece that was added to the main spindle. While it's vanishingly unlikely, there is a remote possibility that the 50 mm piece could come loose and come off the spindle along with the chuck and the clamp. I don't for a second think that it would actually happen, but considering it's intended as a safety feature it seems better to go belt-and-braces and make it out of solid.

Right, that's enough waffle, onto some spindle making. I started by chopping the 50 mm diameter EN1A bar into two pieces, yet again feeling grateful for a horizontal bandsaw to do the hard work for me:

While I'm in spindle-making-mode, I'm going to turn the off-cut into an M33×3.5 spindle as well, but with a plain 30 mm shank on the back. That could be useful if I ever feel the need to mount any wood lathe chucks / face-plates on the metalworking lathe for any reason: the 30 mm shank will go in an ER40 collet and the chuck or face-plate would mount on the threaded nose.

I started with the off-cut first, holding it in the chuck and, with a fixed steady supporting the outer end, facing it and drilling a centre hole:

That was repeated for the other end. A fixed steady is a bit pointless for something that short, but it was a convenient way to set the steady up near the chuck, ready for sliding along the bed and using it for the real spindle:

With the centre holes in both ends of both bars, I could add conventional tailstock support and rough out the shape of the rear of the spindle, leaving every diameter about 1 mm larger than it eventually needs to be:

That left the spindle looking like this, with a long 31 mm section and a shorter 21 mm section:

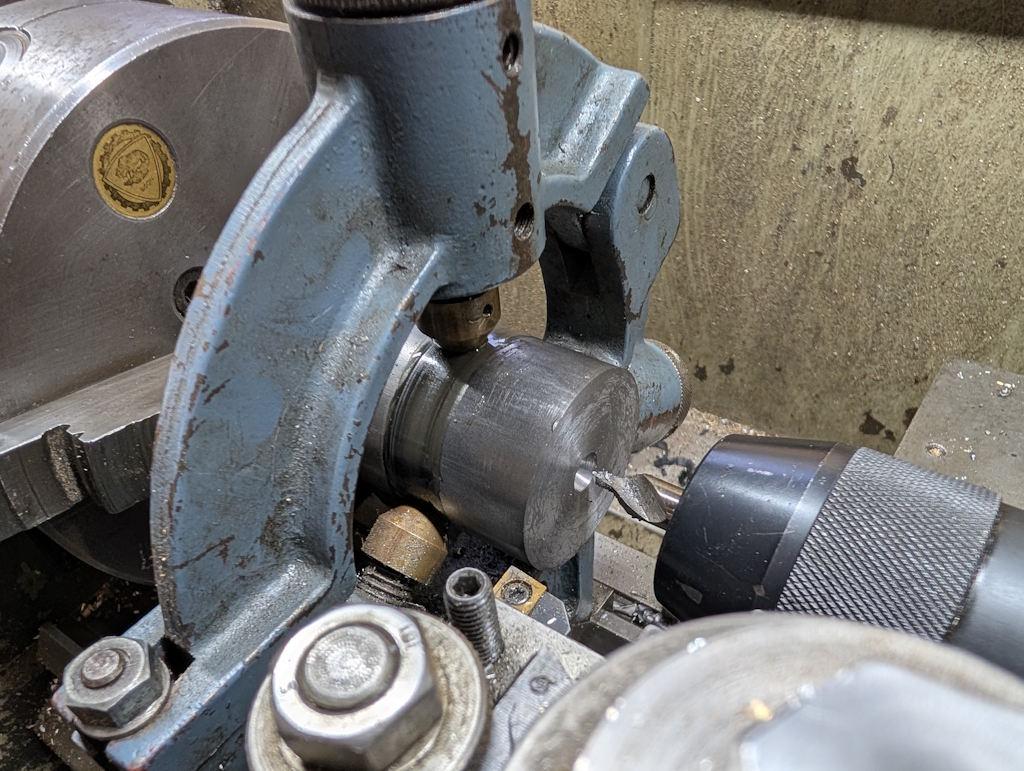

After doing something similar with the off-cut, I mounted the spindle between centres and roughed out the nose, again staying 1 mm over size:

Once again, that was repeated on the off-cut, resulting in these two pieces, shown alongside the old spindle for scale:

With the roughing out done, the next job will be to turn all the remaining features. A few of them (34 mm chuck register and the 30 mm bearing seats) have quite critical dimensions, so it's important that the part isn't too hot when turning them (otherwise it'll shrink as it cools and could end up under-size). They were very hot after roughing out (hot enough that I needed to wear gloves to remove them from the lathe), so I'll leave them overnight to cool down before moving onto the next stage.

Page 45 of 65

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page