Woodturning Lathe Build Process

Page 47 of 65

Posted 23rd December 2025

Fiddlesticks. I've made a mistake on the spindle and am feeling very annoyed at myself.

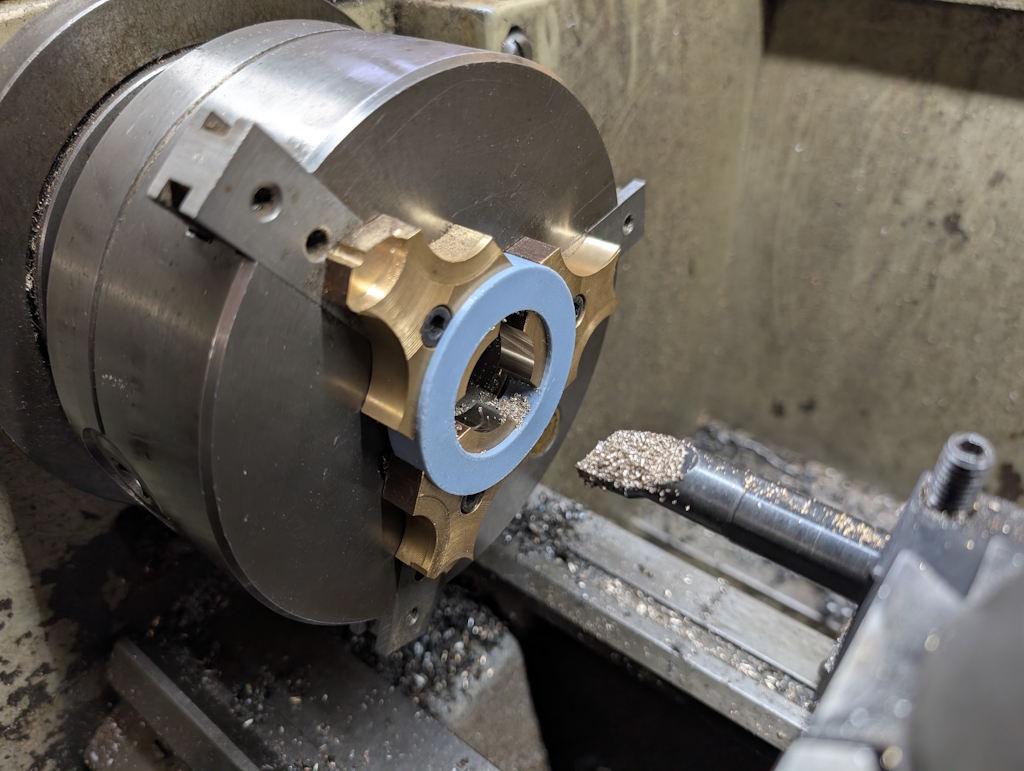

This morning, I started by mounting the soft jaws in the chuck, clamping them down on a 3D-printed helper and boring out the centre to 30 mm:

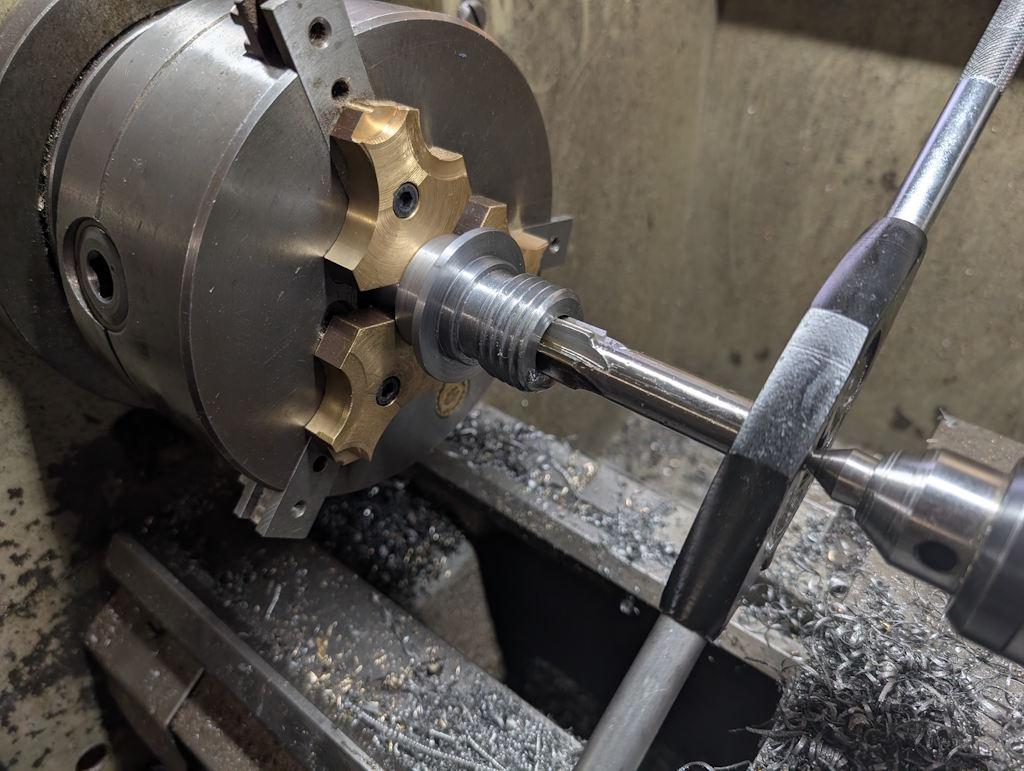

I could then mount the spindle in the soft jaws with the jaws (which should be very accurately concentric with the lathe axis having been bored in place) holding the bearing surface nearest the nose. I drilled 10 mm then 13 mm deep enough to meet the hole from the back:

I then fitted a boring bar in the tool post and used the (previously set to the correct angle) top slide to bore the taper socket:

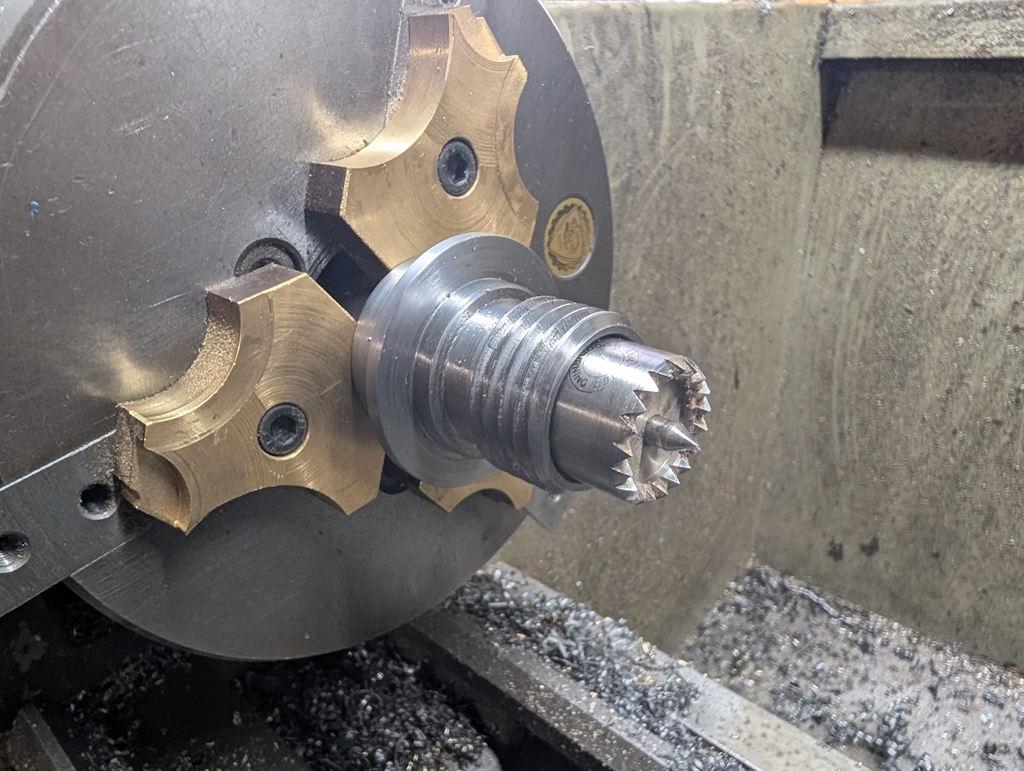

Finally, I did a couple of gentle turns with the Morse taper reamer to clean up any machining marks:

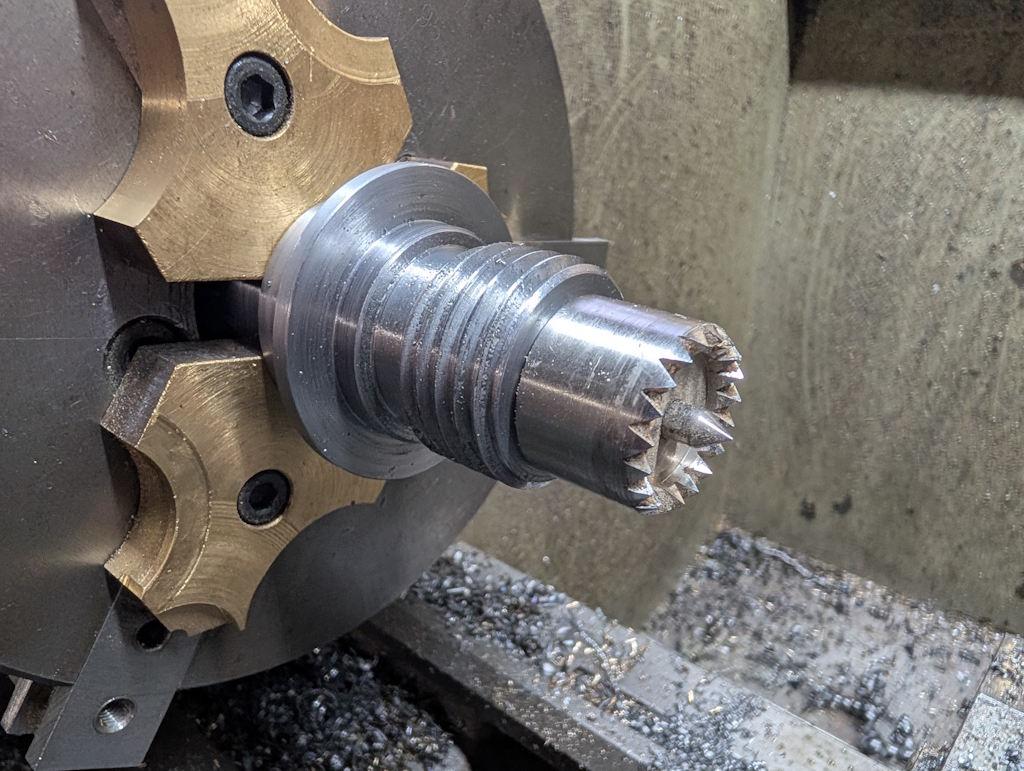

It was then that I realised that I'd made the taper too big. I'd been checking the diameter quite often near the end of the operation but the tool had started making a slightly rough noise so I changed the tip for the last pass. I think the old tip had been more badly damaged than I'd realised and that last pass with the new tip took quite a heavy cut. It's also possible that I mis-measured on the previous passes (it's quite hard to measure the outer end diameter of a taper socket), which could have exacerbated the issue.

Anyway, when I came to do a trial fit with a drive centre, it went all the way in and was loose in the spindle:

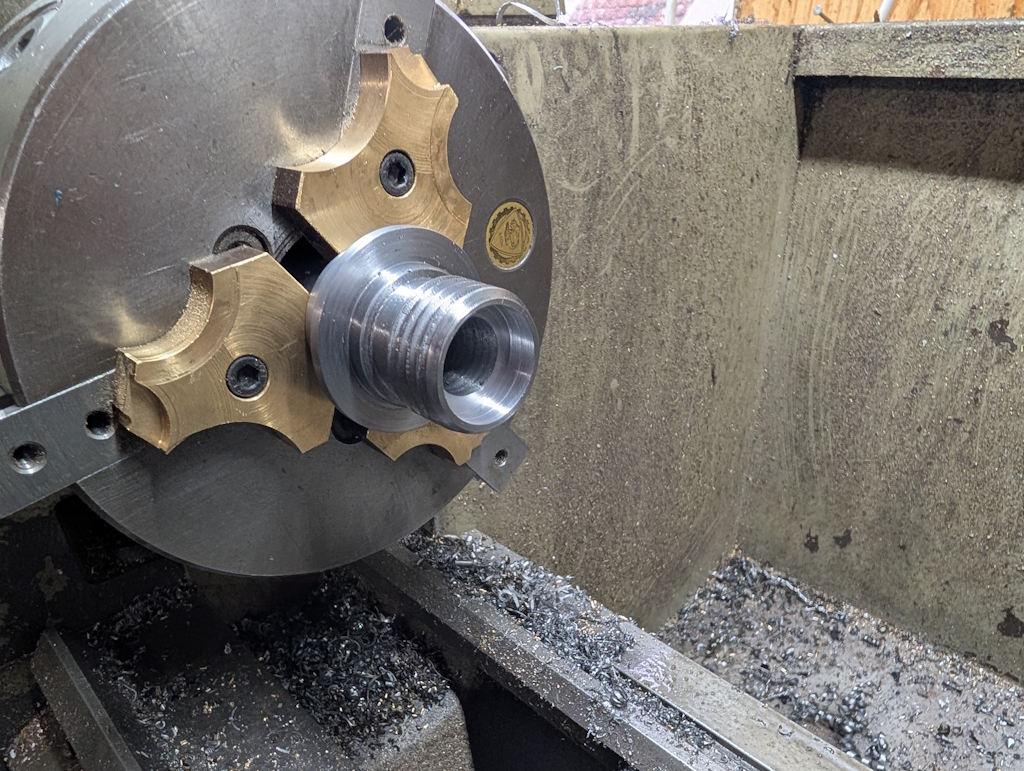

The only thing I could think of doing was to bore the spindle out a bit bigger so that the face is now sub-flush:

That's okay for all the things I've ever put in the spindle bore to date:

However, I'm not happy with it as it could be a bit limiting and will also always remind me of my mistake!

I'm going to finish off the spindle (as the only remaining operation is to cross-drill the hole for the tommy bar), but I've also ordered another (£20) length of 50 mm steel and in due course I'll start from scratch. I doubt that steel will arrive between now and when I go back to work in January, so I'll get on with some of the other jobs in the meantime and, if I get everything else done before the new bar stock arrives, I'll install this spindle and use it to test everything else is okay.

Page 47 of 65

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.

Return to main project page

Return to main project page