Small Mini-Lathe Modifications

This page lists a few small modifications that I've made to the lathe in order to make it more usable. The modifications seemed too minor to be worth giving them their own page, so I've collated them here.

Gear Cover Screws

I replaced the M5 screws that hold the gear cover on with a couple of knurled thumbscrews. These are much quicker to use. The knurled part was made separately and is held on with a grub screw.

Chuck Nut Holder

On the mini-lathe.com site, there are details of a simple modification to give somewhere to store the chuck nuts. They're just M6 nuts, which I have loads of, so if they got lost it wouldn't be the end of the world, but I thought I'd make a holder anyway. Most of the time there is a chuck of some sort fitted to the lathe, so it's very rare that this gets used.

The holder was turned from an M5 stainless cap screw using my lantern chuck. A hole was then drilled in the housing for the EMC filter and the cap screw fixed in place.

Update

The mini-lathe chuck can be fitted to the rotary table / dividing head I have for the milling machine. In order to do this, the M6 grub screws that are used to mount the chuck on the mini-lathe have to be removed from the back of the chuck. I added three M6 coupling nuts (attached with short M6 screws from inside the EMC filter housing) and these can be used as a convenient place to keep the grub screws.

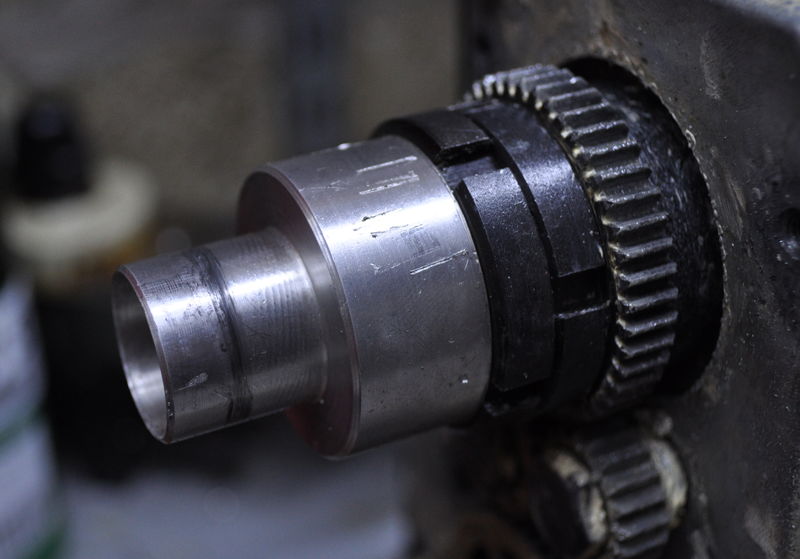

Spindle Extension

This is another very simple modification, based on an idea from Mike's Workshop. Unlike Mike's modification, mine doesn't try to replace the existing spindle extension: it just screws onto the exposed threads at the end of the spindle. The score marks are from tightening it with a pair of pliers. The grey line near the narrow end is where it has rubbed on the gear cover (seen at the top of this page). The extension is removed if I want to use my dividing kit.

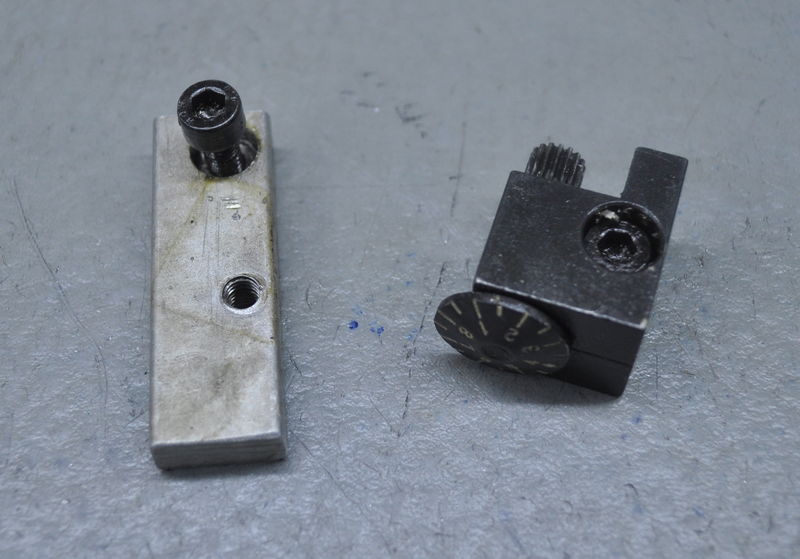

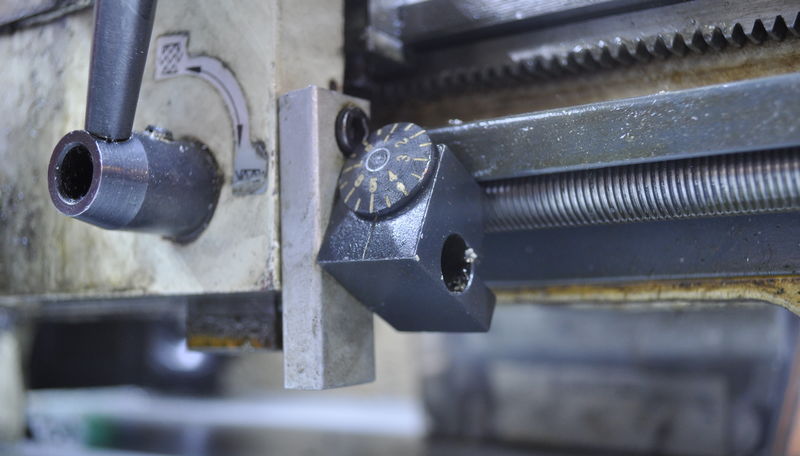

Thread Dial Indicator Mount

The thread dial indicator for the mini-lathe was clearly designed for the C2 mini-lathe, which has an exposed lead-screw. With the SC2 lead-screw cover fitted, the thread dial indicator doesn't fit onto the lathe! This is despite the fact that Axminster sell it as an SC2 thread dial indicator. Making it fit, however, was very simple - a piece of scrap aluminium with two holes in it: one plain and one tapped. Hopefully the picture above is self-explanatory.

In practice, I rarely use it (I tend to prefer to just keep the lead-screw half-nuts engaged). Despite the fact that the SC2's manual explicitly states that it works with all pitches, it's wrong. For a metric thread dial indicator to cover all standard pitches, you need three gears: a 14 tooth one (for 0.7 mm and 1.75 mm pitch), a 15 tooth one (for 1.25 mm and 2.5 mm pitch) and a 16 tooth one (for 0.5 mm, 1.0 mm and 1.5 mm). Given the 1.5 mm pitch lead-screw, no thread dial indicator is actually needed for 1.5 mm pitch screws. I raised this with Axminster's customer support desk and suggested that (at the very least) they should update their website to highlight the limitations of this part, but despite apologising to me for the inaccuracy, they haven't added a warning.

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.