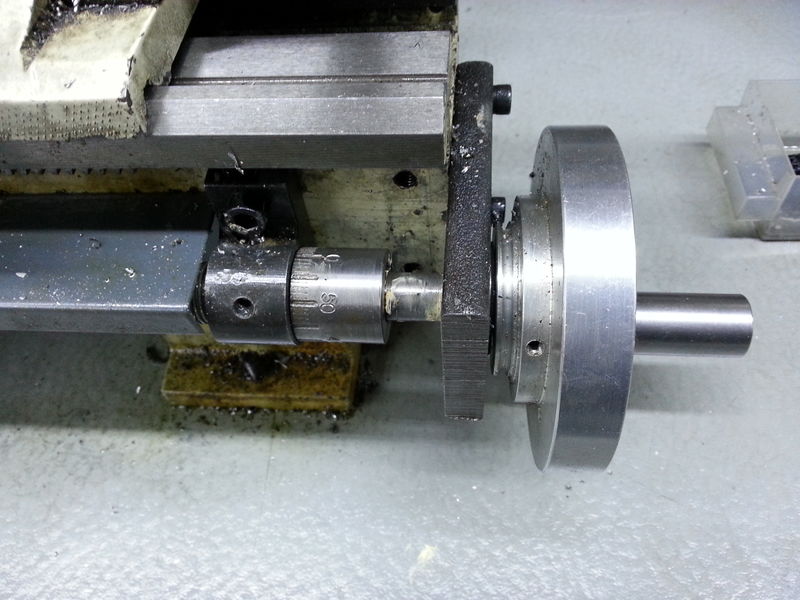

Leadscrew Handwheel

After the cam-lock tailstock, this is probably the most important modification to make to the mini-lathe. Without a handwheel on the leadscrew, it's very difficult to accurately control the position of the carriage. For some situations, you can work round this by aligning the top-slide with the axis, but the leadscrew handwheel is much more versatile. Also, before I had a leadscrew handwheel, I relied on the fine feed power feed for a good finish. With the handwheel, I can generally get a very good finish by hand and I only engage the power feed when I need an extremely smooth result or I'm reducing the diameter by a lot.

Like a great many of my projects, this one is a simplification of the one that is explained in detail on Mike's Workshop. My original plan was to copy the engagement/disengagement mechanism, but I found that it would occasionally slip (resulting in significant errors), so I locked the extension into the leadscrew with a cross-drilled hole and a roll-pin.

I didn't have a milling machine when I made this, so rather than try to make an accurate pillow block, I used a 10 mm plate mounted on the end of the bed. After mounting in the four-jaw chuck, I bored the plate out to accept a bearing. I could then mount the plate on the extension and use some transfer punches to ensure it was mounted in the right place.

This website is free and ad-free, but costs me money to run. If you'd like to support this site, please consider making a small donation or sending me a message to let me know what you liked or found useful.